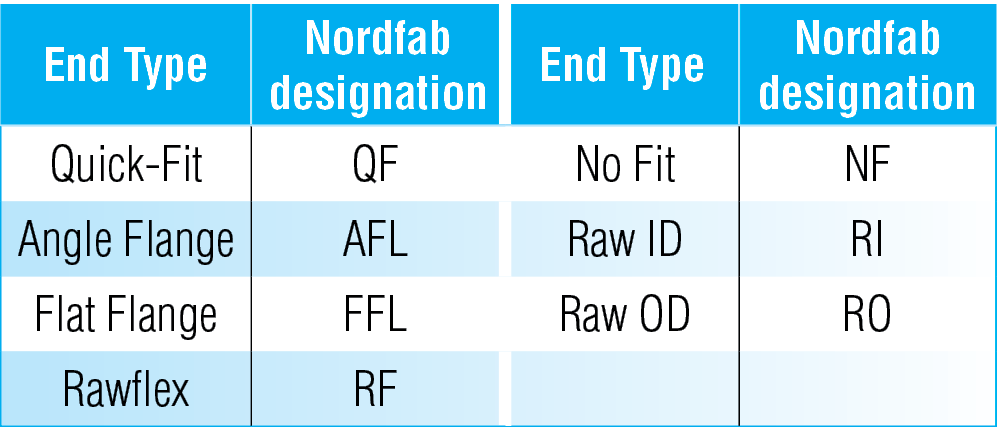

Nordfab offers a variety of end types or connector styles to help you fit our Quick-Fit® duct components together or when you need to add into existing ductwork or connect to machinery.

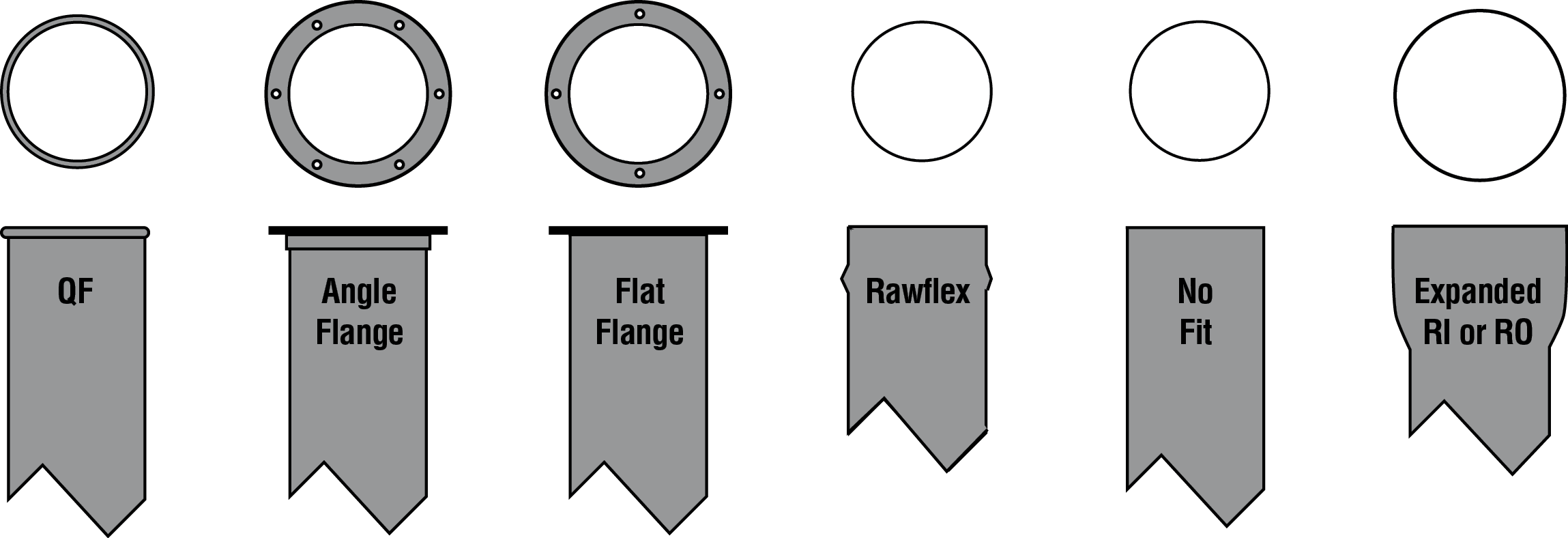

QUICK-FIT: Standard on all Quick-Fit products, the QF® rolled edge end works with our Quick-Fit clamp to make ductwork installation fast and easy. This is the end type provided as standard on most Nordfab products so, generally, there is no need to specify. However, on an order for a custom component with more than one end type, if you need to specify a QF rolled end, please indicate “QF”.

QUICK-FIT: Standard on all Quick-Fit products, the QF® rolled edge end works with our Quick-Fit clamp to make ductwork installation fast and easy. This is the end type provided as standard on most Nordfab products so, generally, there is no need to specify. However, on an order for a custom component with more than one end type, if you need to specify a QF rolled end, please indicate “QF”.

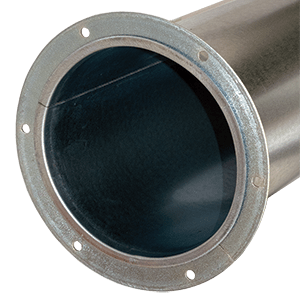

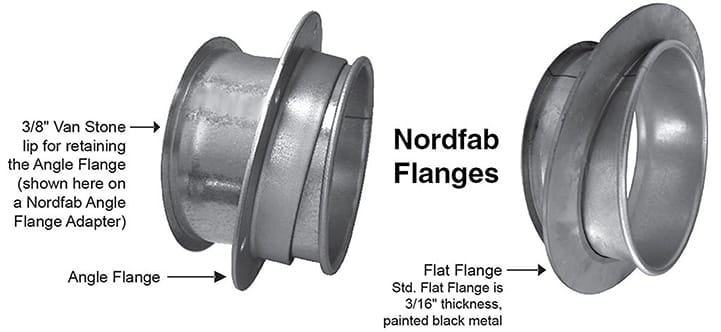

FLANGED: Flanged ends allow you to adapt our QF ducting to existing flanged duct or machinery with flanged connections. We can provide industry standard Angle Flanges or, if you require a custom hole pattern, a Flat Flange. On orders, please indicate “AFL” for angle flange ends or “FFL” for flat flanges (and be sure to provide hole pattern information). Flanged ends are standard on ductwork larger than 24 inches and does not require end specification. See the photos below in the Flanged Ducting section of an Angle Flange and a Flat Flange.

FLANGED: Flanged ends allow you to adapt our QF ducting to existing flanged duct or machinery with flanged connections. We can provide industry standard Angle Flanges or, if you require a custom hole pattern, a Flat Flange. On orders, please indicate “AFL” for angle flange ends or “FFL” for flat flanges (and be sure to provide hole pattern information). Flanged ends are standard on ductwork larger than 24 inches and does not require end specification. See the photos below in the Flanged Ducting section of an Angle Flange and a Flat Flange.

HOSE: If you are adding flexible hose into your ductwork, our RAWFLEX end has a bead around the duct component near the edge to help secure clamps placed around the hose. Order a Hose Adapter.

HOSE: If you are adding flexible hose into your ductwork, our RAWFLEX end has a bead around the duct component near the edge to help secure clamps placed around the hose. Order a Hose Adapter.

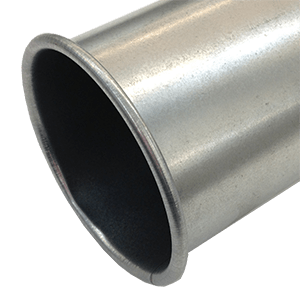

NOFIT: For components with just a plain end, we can provide “No Fit” (no fitting) ductwork. When ordering, indicate “NOFIT” (NF).

NOFIT: For components with just a plain end, we can provide “No Fit” (no fitting) ductwork. When ordering, indicate “NOFIT” (NF).

RAW ID or RAW OD: Applicable only to Expanded Machine Adapters and Reducers, Raw ID (inner dimension) or Raw OD (outer dimension) may be the end type best used when there is a need to slide the duct over or into a connection which has a raw end, such as a machine port.

Please contact Nordfab or your local Nordfab Authorized dealer if you need assistance with determining the right end type for your requirements.

Adapting Quick-Fit® Ducting to Existing Flanged Ductwork

Nordfab’s Quick-Fit (QF) ducting components can easily be connected into existing flanged duct systems using adapters such as our Angle Flange Adapter. The Angle Flange Adapter has a QF rolled edge on one end and an angle flange, which is an industry standard angle ring, on the other end.

Nordfab can also provide Flat Flange ends, which can be customized to your hole pattern requirements.

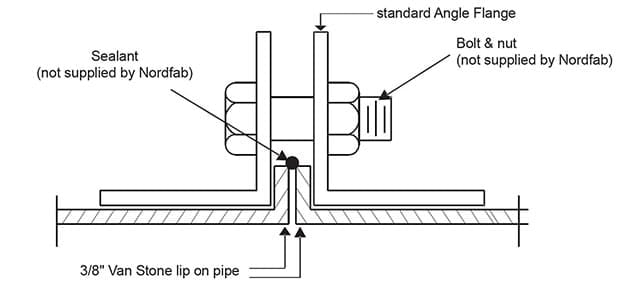

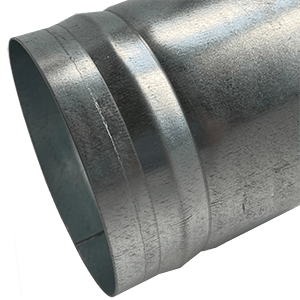

Quick-Fit ducting is available in diameters up to 24″. For larger duct requirements, Nordfab manufactures flanged duct pipe in diameters up to 40″ in standard gauges and up to 72” in heavier gauges. Flanged duct pipe is constructed from sheet blanks 59″ long, rolled with a longitudinal lock-form seam. An industry standard angle flange, made from angle bar stock rolled on edge, is placed on the end of the duct and secured via a Van Stone lip connection. The loose flange allows easy match up to holes on existing flanges. Connection of two flanged pipes is illustrated below.