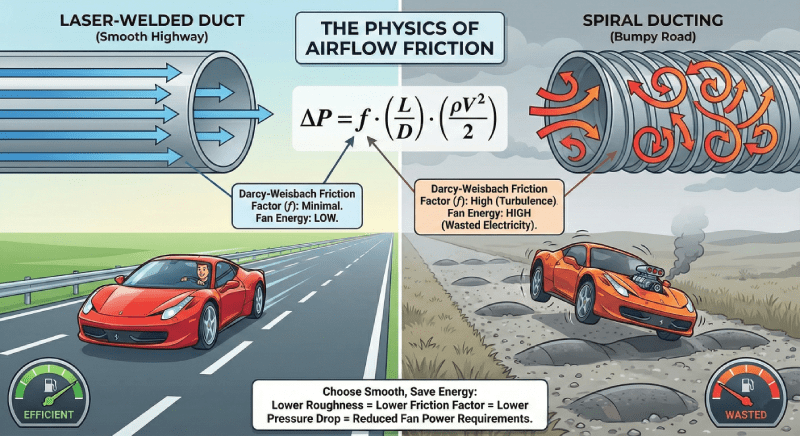

When designing an industrial ventilation system, it helps to visualize the airflow as a car driving down a highway. The efficiency of that car depends entirely on the condition of the road. In fluid dynamics, this "road condition" is measured by the Darcy-Weisbach Friction Factor, essentially a score that tells you how smooth or bumpy your ducting path is.

Consider the difference between laser-welded ducting (such as Quick-Fit) and standard spiral ducting:

These "speed bumps" create turbulence; swirling eddies of air that crash into each other rather than moving forward. This turbulence spikes the Friction Factor (f) in the Darcy-Weisbach equation, the gold standard for calculating pressure loss in turbulent flow regimes.

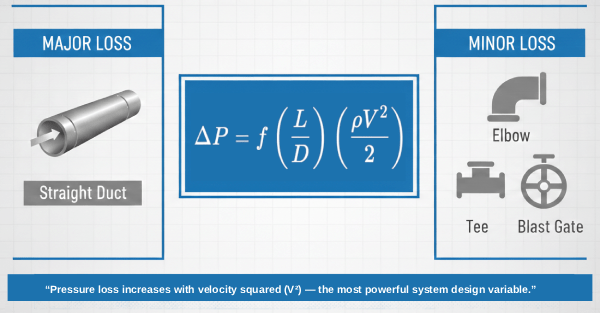

The equation is defined as:

ΔP = Major pressure loss (in. w.g.)

f = Darcy friction factor

L = Duct length (ft)

D = Duct diameter (ft)

ρ = Air density (lb/ft³ — varies with temperature & elevation)

V = Air velocity (FPM converted to ft/sec for calculation)

Crucially, the friction factor (f) is heavily influenced by the pipe's internal roughness. A smooth, laser-welded pipe has an absolute roughness as low as 0.000005 ft, whereas spiral ducting ranges from 0.0003 to 0.0005 ft.

Mathematically, the ridges in spiral ducting increase the roughness factor by nearly 100x. Just as a car engine must work harder to maintain 60 mph on a gravel road than on a highway, your fan must consume significantly more electricity to push air through the turbulence of spiral ducting. Over a long run, choosing the "smooth highway" of laser-welded ducting results in measurable energy savings.

Need a technical consultation? Request a project review with a Nordfab Ducting Specialist.

It looks like you're coming from United States.

Would you like to go to the United States site?